Proof Load and Product Development Testing

The proof load testing, in its most basic iteration, involves applying substantial loads to lifting or rigging machinery, or load-bearing structures, to assess their load-bearing capacity under stress. This procedure serves to evaluate the efficiency and robustness of the equipment or structure. Upon conducting this test, you gain valuable insights into both the operational capacity and the tensile strength of the machine or structure.

The proof load test is frequently conducted utilizing dynamometers or hydraulic cylinders equipped with load cells. Typically, the force applied to the structure or machine ranges from 1.1 to 1.5 times the load capacity of the measuring system. In conjunction with dynamometers or load cells, water bags are occasionally employed to augment the applied weight during testing.

Proof load testing is an integral part of bringing a system design into production. Calculated values alone do not necessarily give an accurate picture of how materials and products will integrate together. Load testing provides empirical data to ensure that products meet specifications and comply with required regulations and quality standards (AS, ASTM and ISO).

Scaffolding Assemblies and Components

Scaffold component testing in Australia is governed by the Australian Standard AS/NZS 1576 series and AS/NZS 1577. These standards provide detailed guidelines and requirements for scaffold design, construction, and the testing of scaffold components. Manufacturers and suppliers of scaffold components are responsible for ensuring that their products meet the required quality and safety standards. This includes conducting quality control checks during manufacturing to detect defects, such as cracks, corrosion, or weaknesses. Testing Methods: Scaffold components may undergo various testing methods, including destructive and non-destructive tests, to evaluate their structural integrity and compliance with standards. These tests can include tensile testing, compression testing, and bending tests. Material Quality: Scaffold tubes, for example, are typically made of steel and must meet specific material quality requirements. The steel used should have the appropriate strength, durability, and resistance to corrosion.

Edge Protection Systems

Edge protection testing in Australia is a critical aspect of ensuring the safety of workers and preventing falls from heights in construction and other industries. Edge protection systems, such as guardrails, safety nets, and barriers, must be thoroughly tested and meet specific Australian standards to provide adequate protection. Edge protection systems in Australia must comply with the relevant Australian standards, primarily AS/NZS 4994.1:2009 "Temporary Edge Protection" and AS/NZS 4994.2:2009 "Temporary Edge Protection Working Platforms. Load Testing: Load testing of edge protection systems is essential to ensure they can withstand the expected loads and forces. Testing may involve applying a specified test load to the system, typically in the form of weights or hydraulic loads. Dynamic Load Testing: In addition to static load testing, dynamic load testing may be performed to assess how the edge protection system responds to dynamic forces, such as wind gusts or impacts from falling objects. Deflection Testing: Edge protection systems must be tested for deflection, which measures how much the system flexes or bends under load. Excessive deflection can compromise worker safety.

Formwork and Props

Props, shoring, and scaffolding used in Australia should comply with AS 3610-1995 "Formwork for Concrete" for general requirements. Additionally, AS/NZS 3610-2010 "Formwork for Concrete" and AS 3610.1-2010 "Formwork for Concrete—Formwork and falsework—Formwork" provide specific requirements and guidelines for formwork and falsework (props) used in concrete construction. Materials Testing: Like formwork, the materials used in props and scaffolding, such as steel or aluminium components, should meet quality standards and undergo testing for strength, durability, and compliance.

Chemical Anchor Points

Chemical anchor proof testing refers to the process of testing and verifying the performance of chemical anchors used in construction and engineering applications. The goal is to ensure that chemical anchors are capable of providing the specified load-bearing capacity and meet safety standards. This testing process helps guarantee the structural integrity and safety of construction projects. Below are the key aspects of chemical anchor proof testing in Australia: Testing Procedures: The testing procedures for chemical anchors typically involve load testing to determine the anchor's capacity to withstand axial, shear, and tension loads. The tests are conducted under controlled conditions to simulate the actual working environment as closely as possible. Quality Control: Chemical anchor proof testing is often conducted as part of a quality control process to ensure that anchors are installed correctly and meet specified standards. Proper installation practices are crucial for anchor performance.

Load Testing of Covers and Grates

AS 3996-2019 "Access Covers and Grates" is the Australian Standard that provides guidelines and requirements for the testing of access covers and grates used in various applications, including road and pavement access, footpaths, and other areas where they may be subjected to vehicular and pedestrian traffic. This standard aims to ensure the safety, durability, and performance of these products. Below are key aspects of the testing of covers and grates according to AS 3996-2019: Testing Categories: AS 3996 categorizes access covers and grates into three classes, each representing different load-bearing capacities. These classes are Class A, Class B, and Class D, with Class D being the highest load capacity.

Testing of Ladders and Stairs

AS 1892 and AS 1657 are Australian Standards that provide guidelines and requirements for the testing, design, construction, and use of ladders and stairs in various applications. These standards aim to ensure the safety, durability, and performance of these structures. Below are key aspects of the testing of ladders and stairs according to AS 1892 and AS 1657. Load Testing: Ladders are subjected to load testing to determine their maximum safe working load (SWL). Load tests involve applying loads to the ladder rungs or steps and assessing the ladder's performance under various load conditions. Deflection Testing: Deflection tests measure the deformation or bending of ladder components under load. The standard sets limits on the maximum allowable deflection for different ladder types. Impact Testing: Impact testing evaluates a ladder's resistance to sudden shocks or impacts. It assesses whether the ladder can withstand accidental impacts during use without failure.

Balustrade System Testing

AS 1170.1 is an Australian Standard that provides guidelines and requirements for the structural design actions to be considered in the design of buildings and other structures. It covers various aspects of structural design, including loads and load combinations. While AS 1170.1 does not specifically address balustrade testing, it does play a role in the design process by providing information on the loads that need to be considered when designing balustrades and guardrails. Local Variations: It's worth noting that AS 1170.1 is part of a series of Australian Standards related to structural design actions, and specific variations may apply to different regions or states within Australia. Engineers and designers should consult the relevant regional or local building codes and standards to ensure compliance. While AS 1170.1 doesn't provide detailed testing procedures for balustrades, it plays a critical role in establishing the load requirements and load combinations that engineers use as the basis for balustrade design. Balustrades must be designed to meet these load requirements to ensure safety and compliance with Australian building codes and standards.

Pool Fence Barrier Testing

AS 1926.1-2012 "Swimming Pool Safety Part 1: Safety Barriers for Swimming Pools" is an Australian Standard that sets out the requirements for the design, construction, and installation of safety barriers, including pool fences, to prevent unauthorized access to swimming pools and spas. Impact Testing: The standard specifies impact testing to assess the strength and durability of the barrier. This includes testing the ability of the barrier to withstand accidental impacts or forces that may be applied to it.

Pool Gate Durability Testing

AS 1926.1-2012 "Swimming Pool Safety Part 1: Safety Barriers for Swimming Pools" is the Australian Standard that provides guidelines and requirements for pool gate design, construction, and installation. While it doesn't specify durability testing methods for pool gates explicitly, it does include requirements and recommendations to ensure that pool gates are durable and function correctly over time. Self-Closing Mechanism: AS 1926.1 requires that pool gates must be equipped with a self-closing mechanism. The purpose of this mechanism is to ensure that the gate closes automatically after it has been opened, helping to prevent unauthorized access. Self-Latching Mechanism: Pool gates should also have a self-latching mechanism. This mechanism ensures that the gate latches securely when closed, preventing it from being easily opened by young children. Latch Release Height: The standard specifies a minimum height for the release mechanism on the pool gate latch. This requirement is intended to ensure that young children cannot.

Other

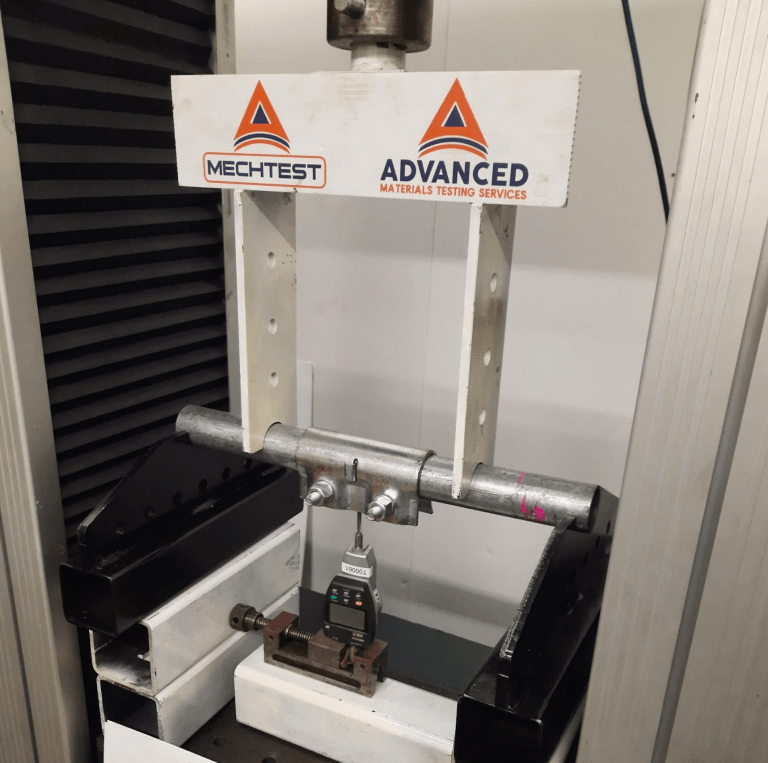

Products and assemblies often require testing that falls outside the norm of traditional testing. Client requirements are vast and varied. We design and fabricate frames, jigs and other bespoke items to ensure custom testing can be undertaken safely and securely to specific standards or client requirements.

Services

Mechanical Testing Custom & Product Load Testing Failure Analysis Welding Quality Assurance Chemical Analysis Polymer & Geomembrane TestingContact us

If you would like to contact us anytime to discuss your mechanical testing requirements, you can:Call us

(07) 3277 0100Email us

info@mechtest.com.auMechTest Help Centre

We are here to help in whatever way we can. If you can’t find what you are looking for below please contact us.

Menu

Menu

Menu

Menu