Failure Analysis and Investigation

Failure analysis and investigation is a process of understanding why components or systems fail to meet their intended purpose. It involves identifying root causes, analyzing materials and conditions, and recommending improvements to prevent future failures. This practice improves quality, safety, and reliability in various industries.

The failure of engineering components and plant can injure workers and the public, cause environmental damage, and lead to lengthy production interruptions. Root Cause Failure Analysis (RCFA) is a systematic approach by which investigators aim to determine and address the root cause of a failure. By addressing the root cause, future failures of same kind can be efficiently and effectively prevented. Advanced Materials Testing Services has a team with extensive RCFA experience, built serving a wide range of industries. Examples of failures that have been successfully diagnosed include(Root Cause).

A WIND TURBINE BLADE FRACTURING

A wind turbine blade fracturing 100 mounting studs and falling from its tower

- Root cause: Design problem — Vibration induced loosening of studs, which led to fatigue cracking

A CAUSTIC TANK BURNER TUBE DISTORTING

A caustic tank burner tube distorting and rupturing

- Root cause: Material selection — The selected tube material had insufficient heat resistance

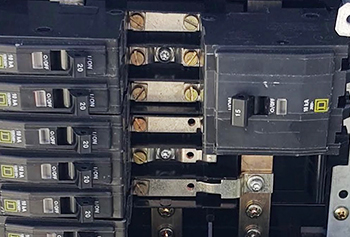

CIRCUIT BREAKER BOLTS FRACTURING

Circuit breaker bolts fracturing

- Root cause: Lapses in quality control — High-sulfur bolts were used without regard for their brittleness

CORROSION OF A COMMERCIAL OVEN RACK

Corrosion of a commercial oven rack

- Root cause: Improper maintenance procedure or schedule — Salty food residues were inadequately cleaned, resulting in chloride-influenced corrosion

MITIGATING UNFORESEEN FAILURES

Because unforeseen failures can have strong negative impacts on the operations, reputation, legal standing, and financial position of a firm, the targeted remediation of future problems represents tremendous return on investment.

EXPERT WITNESS

An Expert Witness is a subject matter expert who is engaged in legal proceedings to provide objective and unbiased opinions based on the facts of a case. The role of the Expert Witness is to clarify, explain, and interpret complex issues in their field of expertise. While the Expert Witness is engaged by a party in a matter (the defendant or the plaintiff), the Expert Witness is not an advocate for the party that engages them — the Expert Witness is obliged to provide unbiased, independent opinions.

If a matter proceeds to court, the Expert Witness may be called upon to give evidence. Prior to proceeding to court, an Expert Witness usually submits an expert report that summarizes the facts of the case and the Expert Witness’s opinions and analysis. A well-written expert report containing findings favourable to the party that engaged the Expert Witness will often result in a settlement rather than a costly court appearance.

METALLOGRAPHIC ANALYSIS

Microscopic examination of polished metal specimens can be used to assess heat treatment, detect degradation, diagnose failure mechanisms, and characterise materials in myriad ways. Advanced Materials Testing Services has materials engineers experienced in the following:

- In-situ metallography aka replication (applicable to boiler tubes and other thermally exposed assets)

- Assessment of thermal degradation and creep damage (VGB Guidelines)

- General characterisation of microstructure and heat treatment

- Assessment of microstructural contribution to failure mechanisms

- Grain size measurement, including prior austenite grain size (ASTM E112, AS 1733)

- Determination of volume fraction of constituents (ASTM E562, ISO 9042)

- Non-metallic inclusion rating (ISO 4967)

- Detection and identification of precipitates, intermetallics, and other constituents

- Graphite classification for cast iron (ISO 945)

MechTest Help Centre

We are here to help in whatever way we can. If you can’t find what you are looking for below please contact us.

Menu

Menu

Menu

Menu