Polymer Properties Testing

Polymer testing is a critical process used to assess the properties and performance of polymers, which are large molecules made up of repeating subunits. Polymers have a wide range of applications, from plastics and rubber to textiles and coatings. Testing is essential to ensure that polymers meet specific quality and performance standards.

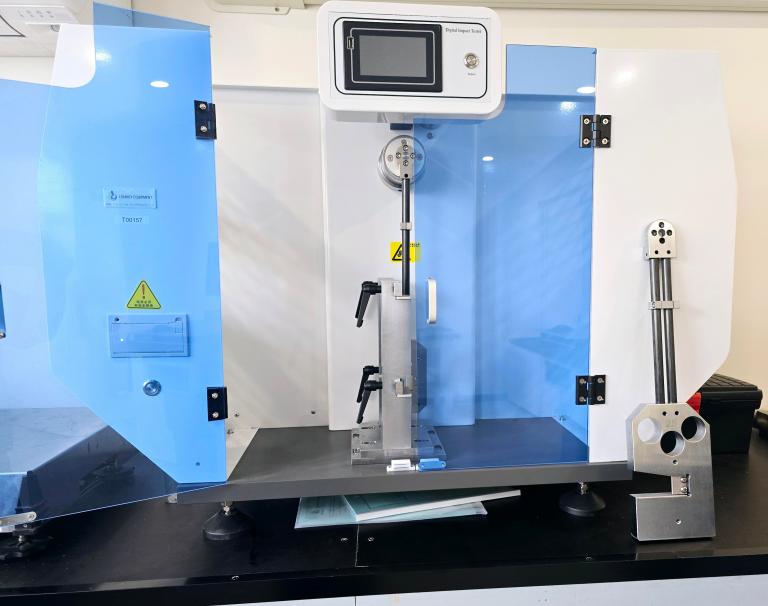

Izod Notched Impact Testing

(Polymers and Composites)

The ASTM D256 standard outlines the procedures for impact testing using the Izod method, aimed at assessing the pendulum impact resistance of plastics. Generally, within the framework of ASTM, the Izod test is employed to measure this resistance according to ASTM D256. In this test, a notched specimen is securely held at one end, and flexural impact stress is applied. The outcome is expressed as the energy absorption related to the specimen's thickness.

Izod impact tests are outlined in standards ISO 180 and ASTM D4508.

Charpy Impact Testing (Polymers & Composites)

The standard ISO 179-1 (non-instrumented impact strength test) delineates the Charpy impact test utilised for assessing plastic materials' impact characteristics, specifically impact strength and notched impact strength. The Charpy impact testing methodology is also referenced in the ASTM D6110 standard.

The Charpy method employs impact tests to evaluate the mechanical behaviour of plastic materials under high strain rates. An abrupt load is applied using a 3-point flexure fixture. Traditionally, the results of this method are expressed in terms of the energy absorption of the specimen.

Thermal Analysis (DSC)

Differential Scanning Calorimetry (DSC) is a thermal analysis technique that measures the heat flow into or out of a sample as a function of temperature or time, allowing for the characterisation of thermal properties and behaviour of materials.

What does DSC measure: DSC measures the variation in heat flow between a sample and a reference material as they are subjected to a controlled temperature program.

Results Interpretation: DSC results are usually presented as a heat flow curve (plotted against temperature or time), which provides insight into the thermal events occurring in the sample.

Fourier Transform Infrared Spectroscopy (FTIR)

Fourier Transform Infrared Spectroscopy (FTIR) FTIR, or Fourier-transform infrared spectroscopy, is a technique that analyses how infrared light interacts with a sample to determine its chemical composition and structure. This method can be used to identify the chemical makeup of various materials, including organic compounds, polymers, and certain inorganic substances.

Melt Flow Index (MFI)

The Melt Flow Index (MFI), also referred to as the Melt Flow Rate (MFR), assesses how easily a polymer flows when in its molten state. This measurement reflects the polymer's viscosity and processability.

MFI quantifies the mass of polymer, in grams, that passes through a specific die (or orifice) over a period of 10 minutes under set temperature and pressure conditions. There is an inverse relationship between MFI and viscosity: a higher MFI signifies a lower viscosity, which leads to better flowability.

MFI testing is standardized according to international standards, including those set by ASTM D1238 and ISO 1133.