Butt Fusion and Electro Fusion Weld Testing

Testing of High-Density Polyethylene (HDPE) butt and electrofusion welds is crucial to ensure the quality and integrity of the welded joints. Various tests and inspections are performed to verify that the welds meet the required standards and performance criteria.

MechTest is Queensland’s leading Laboratory for destructive

testing of HDPE welds.

Visual Inspection

Visual inspection is the initial step to assess the external quality of the weld. It involves examining the weld bead, alignment, and any visible defects such as cracks, voids, or irregularities.

Dimensional Inspection

Dimensional checks ensure that the welded joint meets the specified size and alignment requirements. Measurements are taken to confirm the correct pipe alignment and the fusion zone's dimensions.

Destructive Testing

Destructive testing is carried out on a sample of the welded joint to assess its mechanical properties. Common Destructive testing are.

Butt Fusion Tensile Test ISO 13953

The butt fusion tensile test ISO 13953 is a mechanical test used to evaluate the strength and integrity of the butt-fusion joints in High-Density Polyethylene (HDPE) piping systems. This test assesses the joint's ability to withstand axial (tensile) forces, which are important for determining the reliability and performance of the welded joints. The results of the HDPE butt fusion tensile test are analysed to determine the tensile strength of the joint. Tensile strength is the maximum stress the joint can withstand while being pulled apart. Ductility is another mechanical property assessed these measures its ability to undergo plastic deformation without breaking. In the context of HDPE butt welds, ductility refers to the joint's ability to deform and stretch before failure when subjected to tensile or other mechanical forces. The ductility of an HDPE butt weld is an essential property to ensure that the joint can withstand mechanical stresses and maintain its integrity in various applications.

- Tensile Testing of Butt Fusion Joints – 90-1200mm – ISO 13953

- Peel Decohesion Testing of Electrofusion Joints – ≥90mm – ISO 13954

- Decohesion Crush Testing of Electrofusion Couplers and Saddle Assemblies – 16-225mm – ISO 13955

- Decohesion Testing of Electrofusion Saddle Joints and evaluation of ductility at the fusion interface – Any Size – ISO 13956

- Decohesion Strip Bend Testing of Electrofusion Saddle and Coupler Assemblies for evaluation of joint interface – ISO 21751

- Flexural Bend Testing of Polymers – BS/EN 12814-1

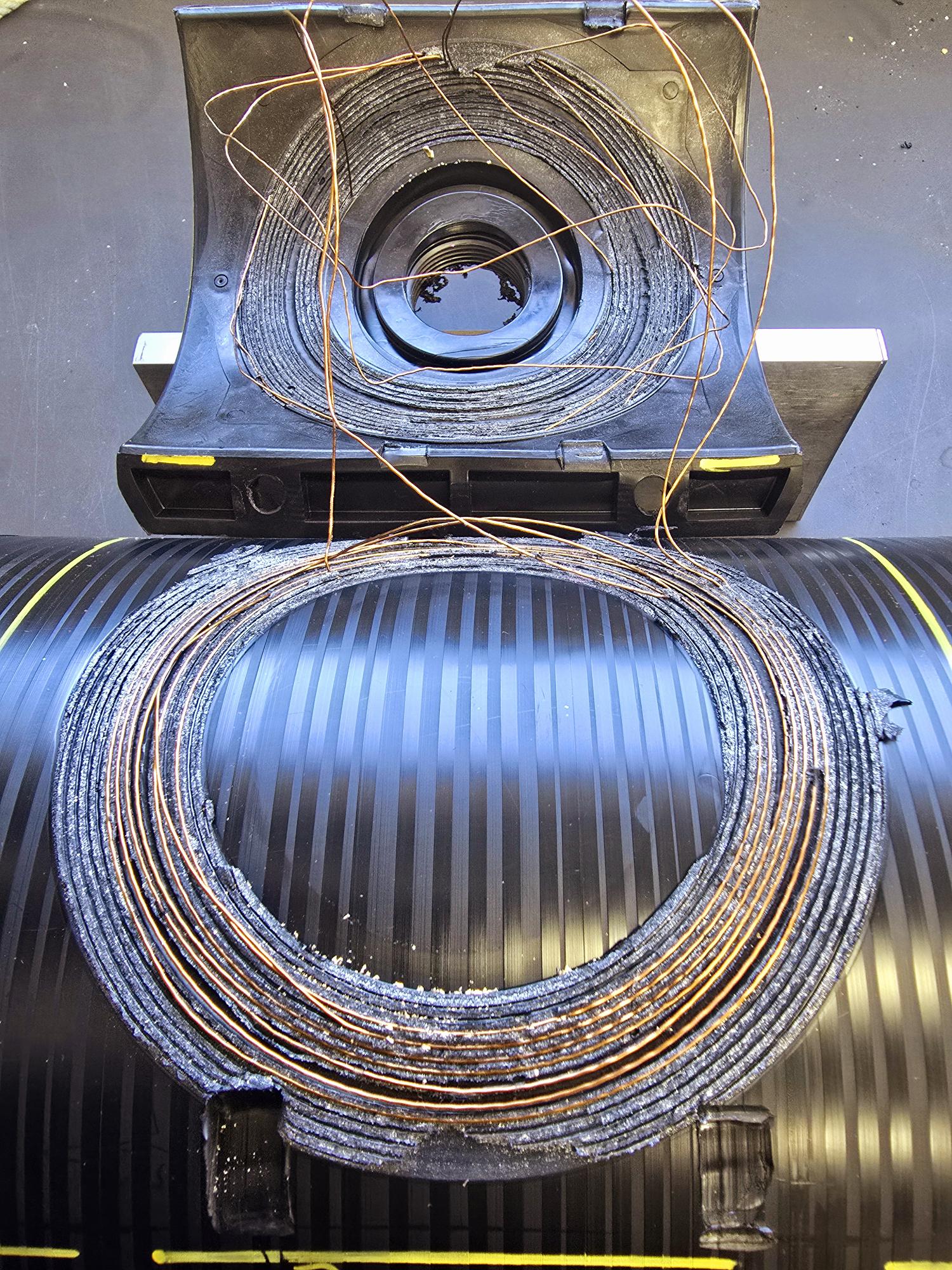

Electro Fusion Peel Test ISO 13954

The electrofusion peel test ISO 13954 is a specific mechanical test used to assess

the strength and integrity of electrofusion joints in high-density polyethylene

(HDPE) piping systems. This test is essential to ensure that the welded joints can

withstand the mechanical stresses and environmental conditions they may

encounter during their service life. The electrofusion peel test evaluates the

bonding strength between the electrofusion fitting and the HDPE pipe.

Analysis:

The results of the electrofusion peel test are analysed to determine the bonding

strength and fusion quality between the electrofusion fitting and the HDPE pipe

surface.

ISO 13955 Crush Testing

– Electrofusion Joint Integrity Assessment

ISO 13955 Crush Testing is a destructive test method used to evaluate the quality and integrity of electrofusion welded joints, particularly in polyethylene (PE) piping systems. This test helps assess whether a weld has been properly executed and can withstand external mechanical stresses.

Electrofusion Saddle Testing (ISO 13956)

We offer destructive testing for electrofusion saddles and top tee assemblies, helping clients identify potential issues in their welding procedures.

We conduct joint tests on electrofusion welds in compliance with ISO 13956 standards. Our services cover destructive testing of electrofusion assemblies using fittings, such as saddles for pipe sizes 90mm or greater, ensuring compliance with ISO 13956.MechTest Help Centre

We are here to help in whatever way we can. If you can’t find what you are looking for below please contact us.

Menu

Menu

Menu

Menu