Metallurgical Services

The analysis of metallic materials through metallurgical testing is a crucial process for comprehending their composition, structure, and properties. Industries such as manufacturing and construction rely on this scientific technique to ensure quality, safety, and optimal performance. Methods employed include chemical analysis, microstructural examination, mechanical testing, corrosion assessment, among others. This procedure enables the utmost optimization of material use, design, and reliability.

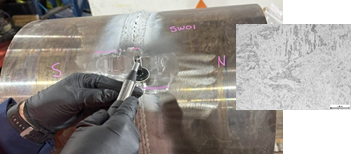

Ferrite Testing

Accurate and rapid testing methods are crucial for high-performance Austenitic and duplex stainless steel components and welds. Ferrite testing is a precise and cost-effective technique that provides valuable insights into the material's ferrite percentage. Its widespread use in various industries has revolutionised the understanding and analysis of these components' behaviour and properties. By conducting ferrite testing, professionals can make informed decisions, optimise material performance and efficiency, and drive higher levels of productivity, profitability, and success in their respective fields.

- Mining

- Oil and Gas

- Power Generation

- Manufacturing

- Construction

- Chemical Industry

Ferrite is a critical microstructural phase that directly affects the mechanical and corrosion performance of stainless steel and welds. Through our advanced testing techniques, we accurately measure and analyse the ferrite content in your components and provide you vital information for assessing material integrity, determining corrosion resistance, and evaluating weld quality.

Our experienced team utilizes advanced equipment and follows industry best practices to deliver reliable and precise ferrite measurements. With our Ferrite Testing service, you can make informed decisions about material selection, optimize manufacturing processes, and ensure compliance with industry standards.

Metallurgical Replication

Metallurgical replication is a non-destructive technique used with portable equipment to obtain precise

replicas of microstructures from surfaces that are in active service. This methodology allows for meticulous analysis without causing any damage to the equipment or requiring its removal. Applications include:

- Creep/thermal degradation analysis

- Material identification

- Crack/corrosion investigation

- Grain size and grain growth analysis

- Sigma phase formation study

It enables informed decision-making, maintenance planning, and cost reduction, thereby minimizing the risk of equipment failure. Metallurgical replication finds applications in various industries, including:

- Power Generation

to examine boiler tubes, heat exchangers, turbine blades, and other components subjected to

high temperatures and pressures.

- Automotive

to evaluate the microstructure and integrity of automotive engine parts, transmission components,

and chassis elements.

- Oil and Gas

to analyse the microstructure and condition of pipelines, pressure vessels, and drilling equipment.

- Manufacturing

to assess the quality and integrity of welds, castings, forgings, and machined parts.

- Marine

to examine the condition of ship hulls and propellers

- Aerospace

to assess the microstructural integrity of critical aircraft components such as turbine blades,

engine components, and structural elements

- Infrastructure

to assess the structural integrity of bridges, pipelines, and heritage sites.

Neutral Salt Spray Testing: Assessing Corrosion Resistance

Our comprehensive Salt Spray Testing service offers a reliable method to assess the corrosion resistance of various materials and coatings. This testing technique involves subjecting samples to a controlled saline environment to simulate corrosive conditions.

Using industry-standard equipment and procedures (such as ASTM B117 and AS 2331.3.1), we conduct rigorous salt spray tests to evaluate the durability and performance of your products. By exposing samples to a corrosive atmosphere, we can accurately determine their resistance to corrosion, providing valuable insights for quality control and material selection.

Our experienced team ensures accurate and consistent results, enabling you to make informed decisions about product design, manufacturing processes, and protective coatings. With our Salt Spray Testing service, you can confidently verify the durability and reliability of your materials, ensuring they meet the required corrosion

resistance standards.

MechTest Help Centre

We are here to help in whatever way we can. If you can’t find what you are looking for below please contact us.

Menu

Menu

Menu

Menu